WHY PIPE RELINING?

The most cost-effective and efficient way of repairing broken, collapsed and missing sections of drains, either above or below ground, without the need of costly excavation, repairs or replacement.

The most cost-effective and efficient way of repairing broken, collapsed and missing sections of drains, either above or below ground, without the need of costly excavation, repairs or replacement.

SAVES YOU MONEY

The pipe relining process eliminates the costly excavations and replacement of existing pipelines in conjunction with all the other associated costs involved.

STOPS LEAKS

Cured-in-place epoxy lining moulds to the internal diameter of the host pipe creating a structural seamless ‘pipe within a pipe’.

Increases Flow Capacity

Newly relined pipelines increase flow capacity due to the new smooth inner lining of the pipelines.

No destruction

Using systemised methods SA Pipe Relining is capable of relining pipelines through inspection openings or any from of access to the pipeline.

No disruption to your routine

The lining process is non intrusive and clean allowing your routine to be maintained with minimal disruption and maximum cleanliness.

No damage to ROADS, paths or landscaping

Avoid costly expenses involved in excavations, replacement of pipelines and reinstatement of affected areas.

Using the latest and most advanced Epoxy Pipe Relining Technology – SA Pipe Relining delivers a trenchless cost-effective solution to internal wall drain repairs. With the added advantage of relining junctions, changes in direction and pipe sizes, as well as start-stop relining and sectional repairs, SA Pipe Relining is capable of meeting all pipe repair requirements.

Relining repairs to sewer, stormwater, vertical stacks, downpipes or other pipelines in situations without costly excavation or replacement is today’s technology solution. Why replace when you can reline.

With SA Pipe Relining’s capability of completing sectional repairs or entire mainline relines on pipelines from 40mm to 1600mm diameter on sewer and stormwater lines, the economic and environmental advantages this technology and systems has to offer has proven very desirable for homeowners through to water authorities.

REPAIR YOU BROKEN DRAIN TODAY

Our process begins with a customer consultation and CCTV inspection of the drainage system to determine and locate any problems within the drains. The footage is recorded in full colour onto USB format and a complete report is created detailing findings.

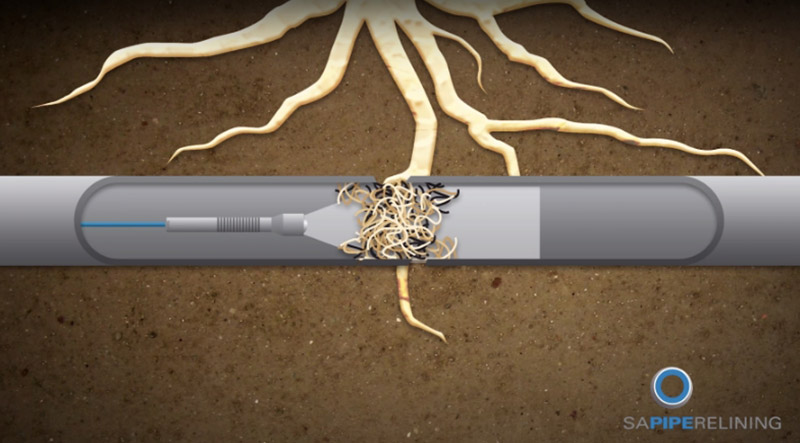

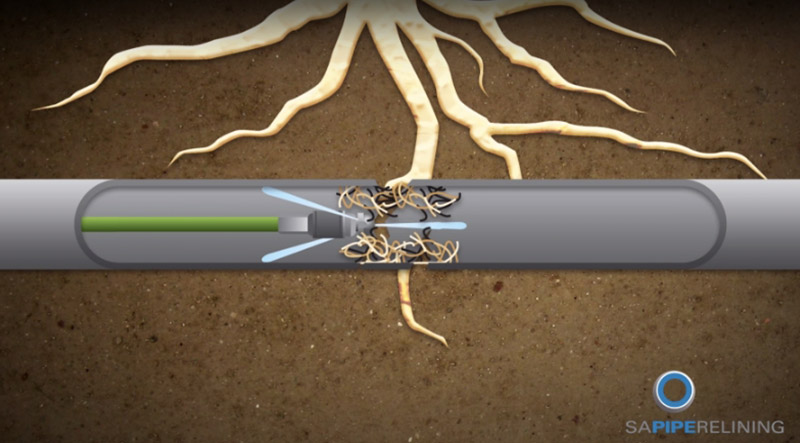

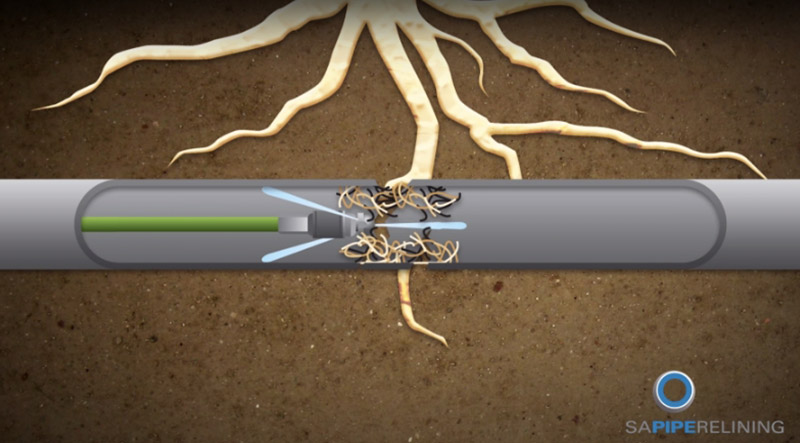

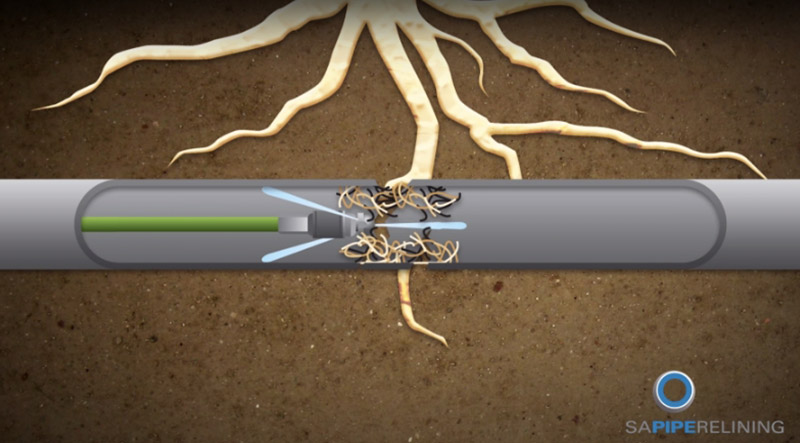

We then hydrojet the drains using a high pressure water cleaner, to descale the internal bore of the drain removing any roots or obstructions, preparing the drain for relining. This ensures the internals of each pipeline are thoroughly and uniformly cleaned.

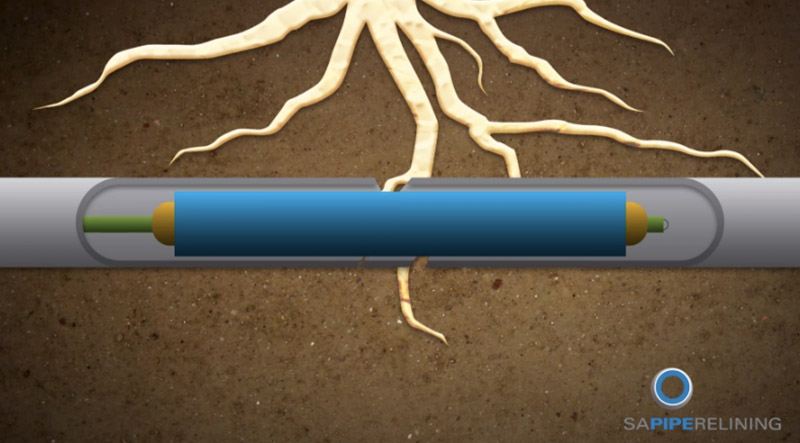

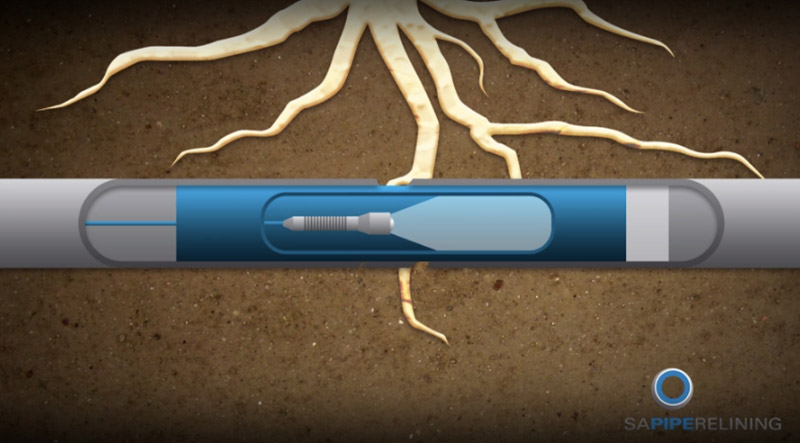

A custom made liner and bladder is manufactured and then inserted into the drain and carefully pulled into position spanning over the damaged section of drain.

The bladder is inflated using compressed air which expands and forces the epoxy filled liner to conform and bond to the internal bore of the existing drain. The liner is then left to cure.

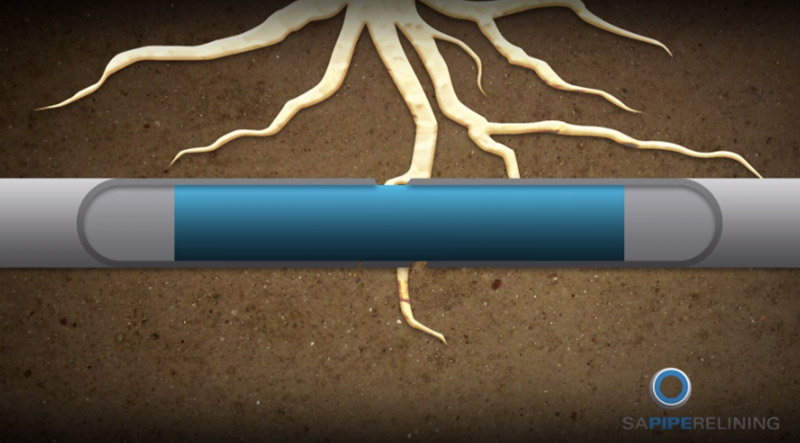

Once cured the bladder is deflated and removed leaving the newly created structural liner set in place, creating a ‘pipe within a pipe’.

A final CCTV inspection is conducted and the pipe is ready for full use. A lining report detailing the completed job is then prepared for the client.

The result; a creation of a smooth, seamless pipeline or sectional repair resulting in a ‘pipe within a pipe’ capable of withstanding pressure, root penetration and smoothing out all misalignments, cracks and missing sections or drain.

The seamless and jointless structure creates a smooth internal bore where calcification can no longer occur as deposits will not stick to the inner walls of the new epoxy barrier lined pipe.

Millions of linear meters of pipelines have been restored worldwide using this simple but effective technology. SA Pipe Relining has both the experience and advanced technical knowledge to meet your specific needs. The applications for relining are endless and regardless of the depth or height of the pipeline or corrosive nature of the environment, SA Pipe Relining has a solution at hand.

REPAIR YOU BROKEN DRAIN TODAY

Investigate the problem today and get to the bottom of what’s causing your drains to continually block.

SA Pipe Relining has been repairing and rehabilitating residential sewer drains since 1999 without the need for messy and costly excavation. Our specialised pipe rehabilitation techniques and experience offers our customers, practical, least intrusive and best environmentally friendly solutions for drain repairs, providing long-lasting and affordable results.

We repair broken drains, collapsed and even missing sections of drains either above or below ground, without the need of costly excavation, repairs or replacement.

We specialise in all types of broken drain repairs including, sewer drains, stack drains, junctions, floor traps, stormwater drains, downpipes (heritage listings) and pump lines, in all materials, lengths and sizes.

If you suspect that your drain is not performing correctly, call us today and we’ll show you the cause of the problem with our CCTV drain equipment and provide you with options on how to fix it!

SA Pipe Relining are the blocked drain specialists. We’ll not only clear your blocked drain but we’ll get to the root cause. Using CCTV equipment, we’ll identify the cause of the blockage and provide you with the best, most cost-effective solution to reline through the problem section.

Repairing cracked, broken and even missing sections of drains below ground are our speciality. Using custom built drain cleaning tools and relining techniques, SA Pipe Relining rebuild your drains, creating a new pipe within a pipe, fixing your drain problems once and for all.

SA Pipe Relining has the expertise to descale, hone and rehabilitate old cast iron corroded sewer drains. Our process removes all corrosion from inside the drains, restoring the drain to its original internal dimension. Relining then completes the process. No more blocked or leaking drains.

Earthenware drains are found in houses that were constructed pre-1970’s and are susceptible to cracking, misalignment and tree root intrusion, causing drains to continually block. SA Pipe Relining can rehabilitate and restore terracotta drains by creating a new “pipe within a pipe”.

REPAIR YOU BROKEN DRAIN TODAY

SA Pipe Relining has some of the most technologically advanced equipment and specialised expertise to CCTV inspect drains and pipelines from 40mm upwards. Variable light intensity controls, self-levelling camera heads and locating sondes all combine to allow extreme versatility and capabilities. With pinpoint accuracy, deep below the ground, CCTV footage enables customised drain repair solutions and accurate repair quotes to be completed.

A hydrojet is a high-pressure water hose connected to a powerful nozzle, that pushes out large amounts of water to penetrate drain blockages, cut through tree roots and descale drains.

SA Pipe Relining has the capability of hydrojetting bathroom drains through to Mainline drains. With various techniques and equipment, SA Pipe Relining is fully prepared to combat a wide variety of situations. Hydro jetting cuts and removes tree roots from drains and descales the internal surface of the drain, helping to identify any damaged sections and promote better drain flow

Hydrojet are extremely versatile and are ideal for tight access locations such as undercroft carparks, commercial buildings and strata complexes. Used for both stormwater and sewer its high pressure and complete arrangement of nozzles enable roots and obstructions to be quickly and efficiently cleared. Unique oscillating rear firing nozzles allow for intensive internal pipeline cleaning and de-scouring.

SA Pipe Relining has a comprehensive assortment of nozzles and tools ready to work on some of the most difficult pipeline obstructions and internal pipeline cleaning requirements.

Some video examples of Drain Repairs using Pipe Relining Technology.

REPAIR YOU BROKEN DRAIN TODAY